Originally posted June 23, 2018.

Yes, this is the year. This project has been in Mike’s mind most of his life and was actually started at least 10 years ago. We had returned home from competing with the ’34 Ford roadster at the Salt Flats and Mike began thinking about stepping up to a streamliner. He put together a couple of rough sketches and presented to his artist friend, Jim Norris. Mike asked Jim to draw up some more professional renderings. As the story goes, instead Jim insisted that we provide him with a block of balsa wood. The ultra-talented Jim carved and painted a scale model of the streamliner.

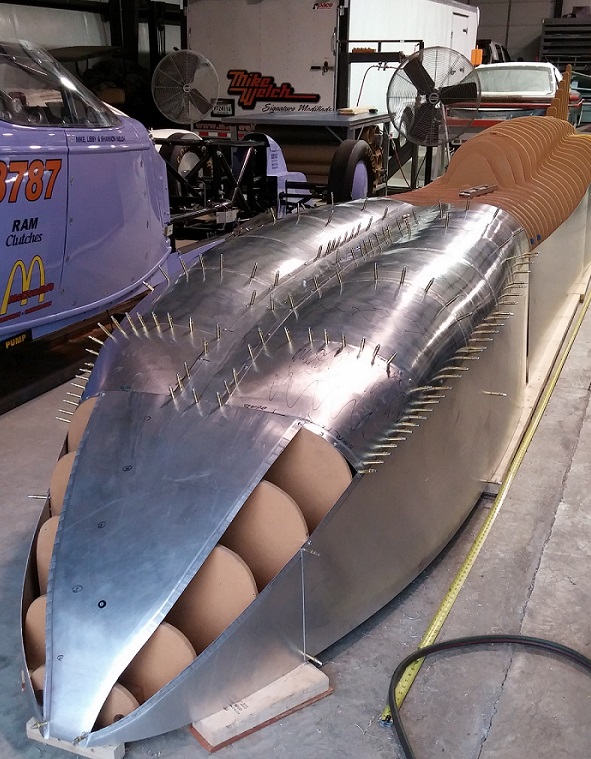

Over the next year or so, the model was reviewed by the Penske group in Mooresville for its aerodynamics. They provided us with a set of CAD drawings. The model then went to Design Works, also of Mooresville, for scanning and creation of additional CAD drawings. A few modifications were made along the way. Then several engineers from Sonoco Products Company cleaned up the two sets of CAD drawings and provided us with one working set. Those CAD drawings went to a cabinet maker near Charlotte who cut the “slices” of the car on a CNC router. The collection of “slices” were then mounted to a wooden base at 6-inch intervals and became the buck for shaping the aluminum body panels of the streamliner.

The buck became a fixture in the shop as Mike went on to other projects. About 3-1/2 years ago we decided that the time was right to get serious about the streamliner build. Naively we first planned to complete it in a year. As the months passed we had to admit the project was bigger than that and now we have been at it for over 3 years.

During the time when we were working toward getting the buck created we got the opportunity to purchase Micky Thompson tires. These tires are capable of travelling at speeds of 400 mph + and are well-known among land speed racers. They are manufactured in very limited quantities so we had to work through a waiting list in order to get them. We had to have wheels specially designed for the tires. Mike chose to have Ken Huff construct the wheels. He is located on the west coast while we are in South Carolina. Many conversations, measurements, photos and materials passed back and forth between us. Amazingly, the end result was a nearly perfect fit.

Every car Mike has ever built has been a challenge to move around. They always have very little ground clearance so we are used to maneuvering them to get in and out of the trailer. With the streamliner being approximately 1-1/2 inches off the ground and 26 feet long, the level of difficulty is multiplied tremendously. After one very long afternoon and evening we spent getting it loaded to display at a local event Mike decided a dolly system was a necessity. In the lower right of the photo below you will notice the dolly under the rear wheel tub. We will trailer the car with the dolly system in place and the wench will be attached to it. We will also use the dolly system to transport the car around at the Salt Flats.

You can see the chassis and frame are beginning to come along in the photo below.

Now you see the buck in full use. The metal shaping is fascinating to watch. It takes a lot of time hammering and rolling to get each piece ready. Before I understood the development process I watched someone at a race shop do it and thought they had ruined the piece on which they were working.

Here you see the canopy over the driver’s compartment.

This photo shows the tail fin under construction.

The driver’s compartment is a tight fit! Mike has modified it twice since the first configuration. He must be able to get himself out of the car by himself and within a few seconds in case of an emergency.

The completed wing above the double parachute tubes.

The nose in a more complete state.

. . . and after skim coating and body work.

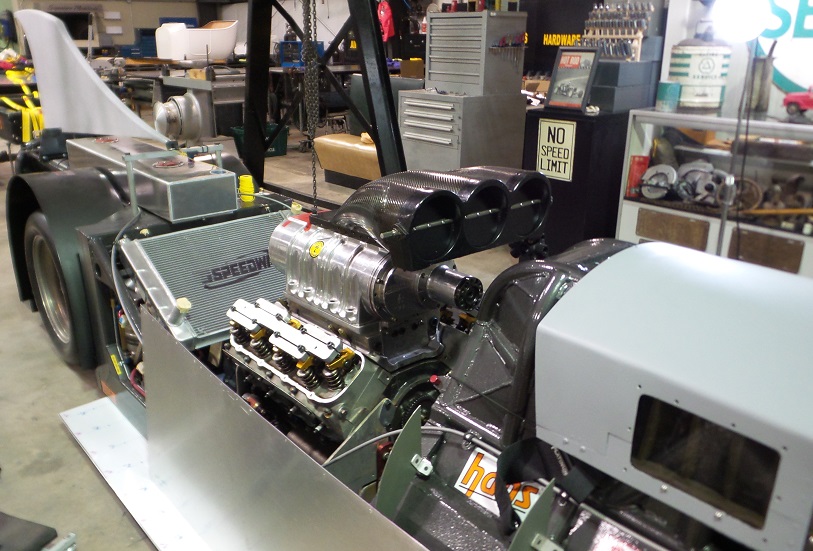

Here you see a mockup of the engine configuration. Gene Fulton of Fulton Competition is handling the engine build and Mike Kopchik of Rage Fuel Systems is supplying the complete fuel system (intake, blower, injector, pump and fuel tune-up). More on Fulton and Kopchik to come.

Body work approaching completion.

Some 70 years old, the SCTA (Southern California Timing Association) is the managing arm of virtually all land speed racing. Streamliners are the top category of land speed racer designs. They are considered to be the fastest vehicles in the world. Current records for this classification are 400 mph +. The basic requirement is that the vehicle have 4 tires (although not necessarily forming a rectangle) and from there creativity is encouraged.

Details of our project at testing:

- 26 feet long

- 42 inches wide at its widest point

- Aluminum body is contoured (like a Coke bottle)

- Weighs 4500 pounds +/-

- Chevrolet engine design of 565 cubic inches

- 14 gallon fuel tank, 6 gallon dry sump oil system and 18 gallon coolant system

- Blown application on methanol

- Ram multi-disk clutch

- Jerico air-shifted 4-speed transmission

- Coleman-produced quick change rear end

- Mild-steel chassis

- All hand-formed aluminum body

- Nascar-style braking system

- Dual parachutes

- Simpson safety equipment

We have competed several times at Bonneville over the years, beginning in 2000. Virtually all runs have been over 200 mph with a top speed of 231 mph (in the lavender ’34 roadster seen in the background of several of the photos). At this point the August trip is for testing purposes only with hopes of a top speed of 300 mph + if possible. First comes tech inspection (which can be tough) followed by numerous shake-down runs required by SCTA.

In closing, I am Libby Welch, wife of Mike. We are doing this as a team effort but Mike is definitely the brains behind it. Our project is solely an in-house effort, short of the engine build, with over 90% of the construction completed within our shop. We will head out to the Salt Flats in a few weeks. Until then I plan to post our progress once a week. While we are at the Bonneville Speed Week event we will post daily to keep everyone up-to-date.